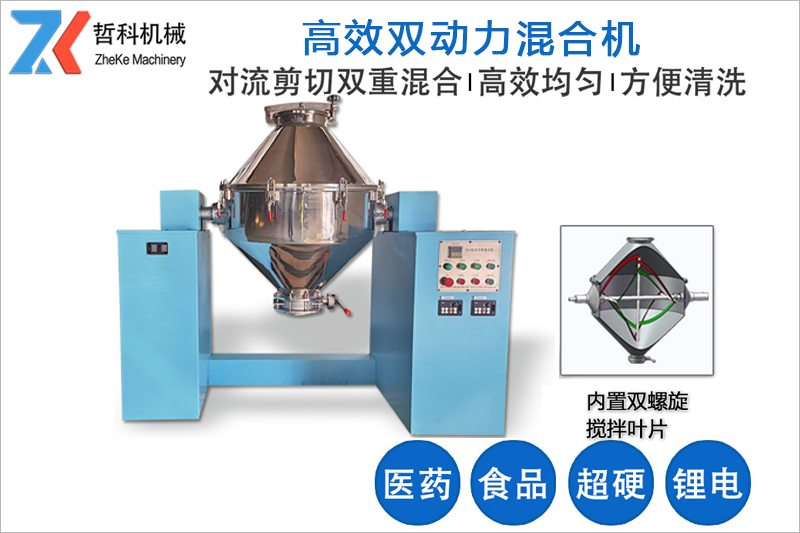

Battery industry in urgent need of high-tech mixing equipment process? As a mixing equipment manufacturer, Zheke Machinery focuses on powder mixing research, is committed to solving powder mixing problems at home and abroad, and is a good help for new material mixing. In particular, the requirements for mixing equipment in the high-tech materials lithium electronic battery industry have always been high, not only the output is high, but the mixing process also needs more new mixing equipment. The dual-power mixing equipment of Zheke Machinery adopts advanced mixing principle and high-end manufacturing technology to solve the urgent need of mixing in the high-tech material industry.

In recent years, the use of polymer electrolytes for lithium-ion batteries has been commercialized and widespread, polymer electrolytes in lithium-ion batteries are both ion migration channels, but also play a role in the diaphragm between positive and negative materials, which has the necessary advantages as follows:

1,?With high ionic conductivity to reduce the internal resistance of the battery;

2,?Can be ignored electronic conductivity to ensure effective isolation between electrodes;

3,?The transfer coefficient of lithium ion is basically unchanged to eliminate concentration polarization;

4,?The electrode material has high chemical and electrochemical stability.

The importance of lithium-ion battery materials is related to the future international development, and domestic and foreign production enterprises have extremely high requirements for the quality of the material itself, so there is an urgent need for efficient mixing processes and mixing equipment.

In the battery industry urgently need to update the mixing equipment process today, you choose the right mixing equipment? Zheke dual power hybrid equipment is the battery industry's main choice of hybrid equipment. Because the general mixing equipment has only one power mechanism, only one or two mixing methods, and the Zheke dual power mixing equipment uses three sets of power mechanisms, which have the characteristics of radial tipping, axial flipping, axial mixing, side mixing and other mixing methods at the same time, to achieve 360 degrees of uniform mixing without dead Angle in the cylinder, and mixing efficiency.