Powder automatic mixing production line not only improves product efficiency, shortens the production cycle, improves product quality, more directly improve the economic benefits of enterprises, in today's personnel cost more and more high, significantly reduce the labor intensity of workers, improve working conditions, improve labor productivity and automation level. This project is mainly used for the automatic production of high-end cement powder. The whole production process basically realizes automatic production, which mainly includes the following systems: raw material storage system, batching metering system, automatic mixing system, automatic packaging system, automatic palletizing system.

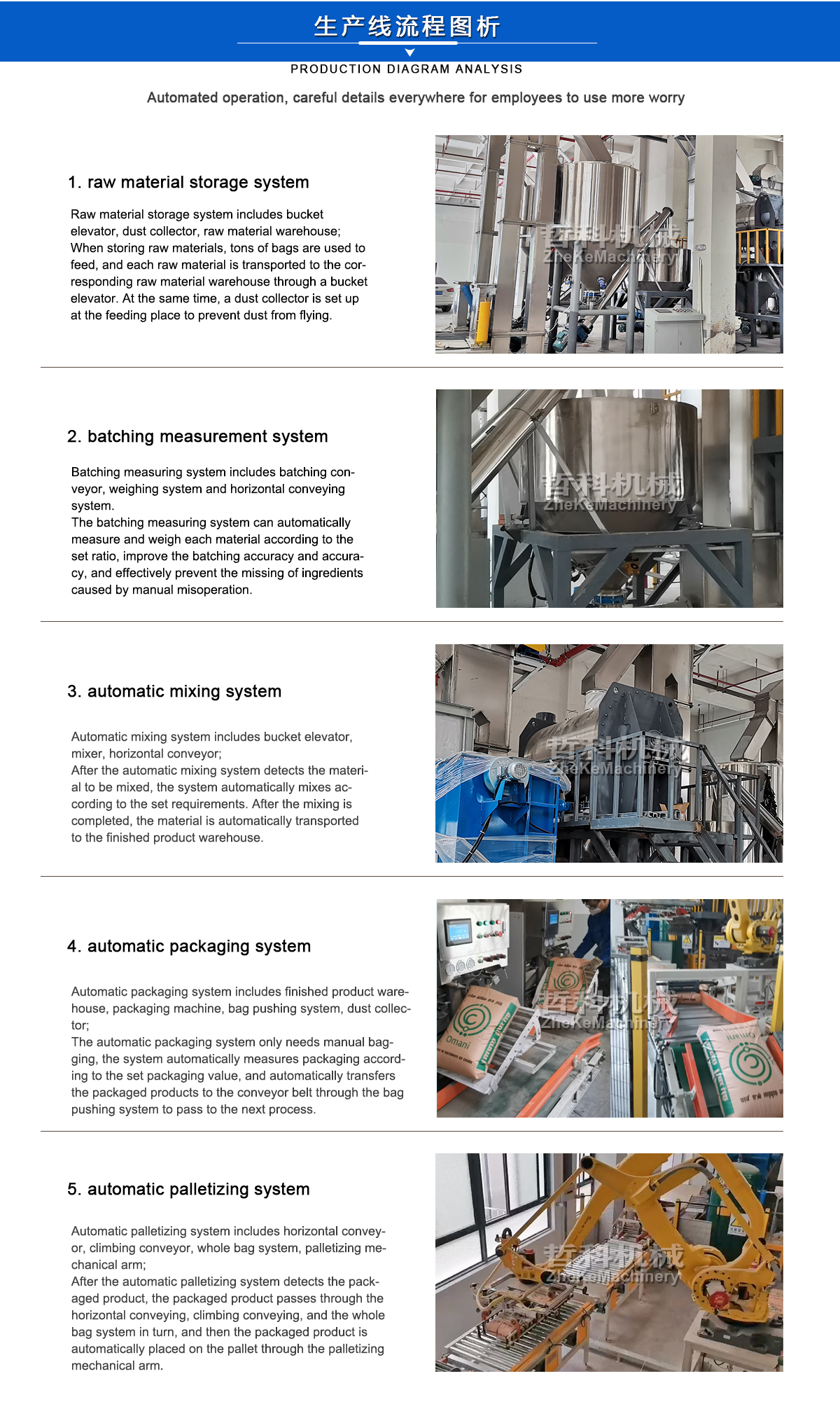

1. raw material storage system: including bucket elevator, dust collector, raw material warehouse; When storing raw materials, tons of bags are used to feed, and each raw material is transported to the corresponding raw material warehouse by bucket elevator. At the same time, dust collector is set in the feeding place to prevent dust from flying.

2. batching measurement system: including batching conveyor, weighing system, horizontal conveying system; The system can automatically measure and weigh each material according to the set ratio, improve the precision and accuracy of the ingredients, and effectively prevent the missing ingredients caused by manual misoperation.

3. automatic mixing system: including bucket elevator, mixer, horizontal conveyor; When the system detects the material to be mixed, the system automatically mixes it according to the set requirements. After the mixing is completed, the material is automatically transported to the finished product warehouse.

4. Automatic packaging system: including finished product warehouse, packaging machine, bag pushing system, dust collector; This system only needs manual bagging. According to the set packaging value, the system automatically carries out metering and packaging, and automatically transmits the packaged products to the conveyor belt through the bag pushing system to the next process.

5. automatic palletizing system: including horizontal conveyor, climbing conveyor, bag system, palletizing mechanical arm; After detecting the packaged products, the packaged products will be placed on the tray automatically through the palletizing mechanical arm after horizontal transportation, climbing transportation and whole bag system in turn.

1. Simple operation, high degree of automation, just press the start button to complete automatic operation.

2. With the automatic control function of the equipment, you can switch between manual/automatic batching functions.

3. The production process is fully automatic to avoid the influence of human factors, improve product quality and reduce personnel costs.

4. Authority management, distinguish between managers and operators, realize the confidentiality of business information.

5. Vertical structure, easy to install, easy to maintain, use its own gravity, reduce intermediate transportation, reduce costs.

6. Improve the working environment and prevent dust from flying.