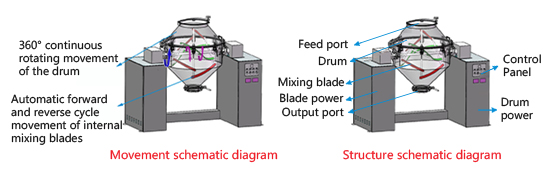

Barrel 360 ° flip movement, with three-dimensional movement, so that the material from the agglomeration to dispersion state and mixed with each other, mixing without dead ends, to achieve full convection of materials, diffusion mixing, to ensure uniform mixing of materials; internal full-size stirring blades forced shear, stirring materials, to accelerate the material flow diffusion effect, the material in the barrel to achieve irregular, very complex movement, to achieve powder shear mixing, so that materials can be fully mixed uniformly, and high efficiency.

—?Innovative process, efficient mixing—

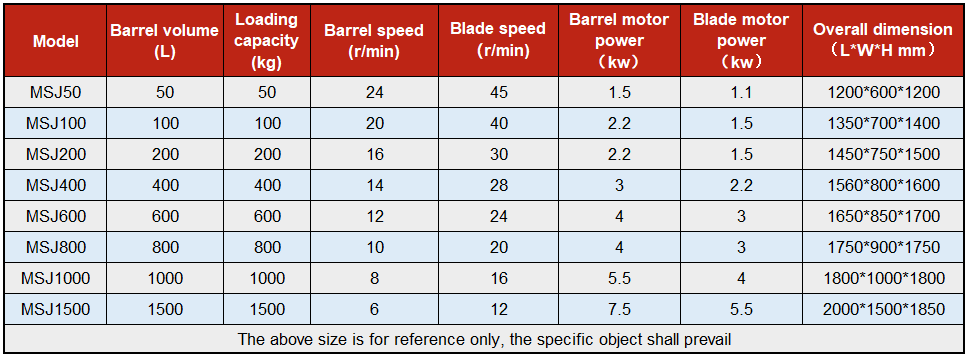

MSJ type double power mixer is a new type, high efficiency, fine container rotary blade mixing mixer, with a variety of powder, granular materials evenly mixed, has a high degree of mixing uniformity, the proportion of large, add less ingredients can also achieve good mixing degree. Barrel volume 50L-5000L, can be customized according to customer requirements.

MSJ type dual power mixer features:

1. Combining the spatial inverse of traditional mixer with the mixing process of forced mixing, the mixing efficiency is higher.

2. Single motor has only one moving part, which is durable and easy to maintain.

3. Bucket and blade double frequency control, according to different material characteristics, by adjusting the speed, to achieve better mixing effect.

4. Double timer to record the total mixing time and the positive and reverse rotation time of the blade.

5. Positive and reverse point function, mixing end, can be adjusted by positive and reverse point function to the direction of the barrel.

6. The loading capacity is up to 85%, twice as much as the traditional mixer.

Structural diagram

—Multiple power, higher efficiency?—

Product characteristics

—?Make with ingenuity and do a good job of each product?—

Related products

![]()

Our advantage

—?Quality assurance, high efficiency and uniformity?—

Product parameter

—?customized, complete specifications—

Matching products

—?Customized to meet various needs—