Condiments are auxiliary supplies in food preparation. It includes a variety of soy sauce, salt, sauce flavor and other single seasoning and chicken essence seasoning and other compound seasoning. Food grade compound seasoning 3D mixer is the standard of equipment selection in the industry.

Dual power 3D mixer in food seasoning, pharmaceutical industry application is good, food grade, pharmaceutical grade material to meet the industry's high health requirements, for mixing and has novel, high efficiency, energy saving, unique performance and other characteristics.

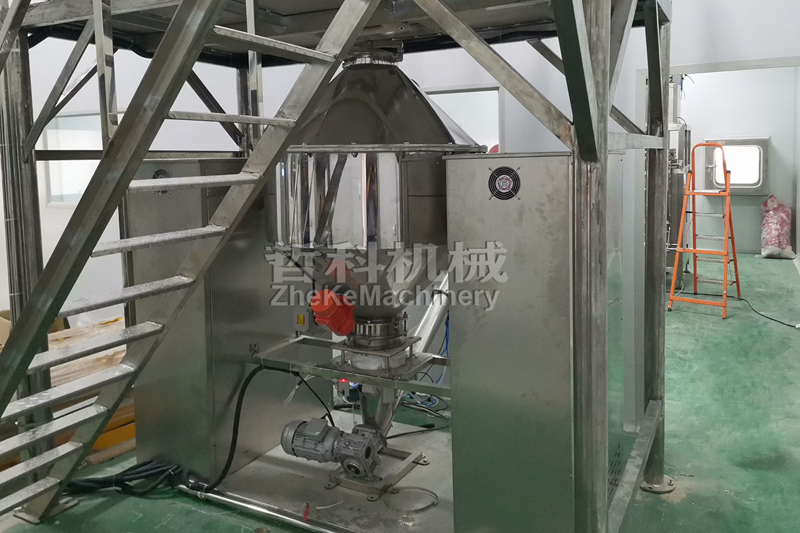

Zeke machinery equipmen t professional 3D mixer manufacturer, is a large scale in China, widely used in mixing, high mixing performance, complete testing equipment, focusing on new and efficient mixing equipment professional manufacturers, in order to solve the industry mixing problems as the goal, is committed to the development of various industries are good to use 3D mixer.

The efficient 3D mixer not only has many mixing advantages, but also has a variety of supporting equipment to meet the different customized needs of various enterprises. The design of the double-power mixing part is very reasonable and ingenious. In the mixing movement, the seasoning powder is mixed by the multiple power mixing from the equipment, so that the material is mixed evenly. High sealing efficiency, the machine adopts end sealing, adjusting the sealing nut, compensation axial pressure sealing method, will not produce leakage powder and dust.

The picture shows the customer site of condiment three-dimensional mixing machine

It is not only a high-end and high-performance mixer, but also has a wide adaptability to mixtures, and has a good adaptability to the mixing of various particles, fibers or sheet materials such as coarse materials, fine particles and ultrafine powders. It is especially suitable for mixing materials with high uniform requirements, large specific gravity difference, large fluidity difference and large particle size difference. Due to its advanced mixing process, even if the material has the difference of specific gravity and particle size, the mixing effect can be achieved by the rapid and violent churning of the staggered mixing blades.

The three-dimensional mixer has low energy consumption and easy operation, and the energy consumption is 1/5 ~ 1/10 of the general mixer in the industry. Fully programmed control, easier operation. The mixing process is intermittent mixing, the discharge valve adopts double door discharge, and the manual and pneumatic discharge forms and the full-size large open bin door are more convenient for cleaning. The dual power 3D mixer is made of high quality stainless steel.